Prevost Piping System compressed air network 100% aluminum

The 100% aluminum concept

The PREVOST PIPING SYSTEM pipes and fittings are 100% aluminum, compact, lightweight and professional strength.

They can be installed easily and quickly for immediate pressurization.

Prevost: An expertise recognized by ASME

As a manufacturer of pipe fittings and subassemblies for compressed air and pressurized fluids systems, Prevost obtained the ASME QPS (Quality Program for Suppliers) General Industry certification. Consequently, our PPS products are guaranteed 10 years.

The PREVOST PIPING SYSTEM range ensures:

- clean, high quality air at all times

- a sealed system

- an optimized flow rate

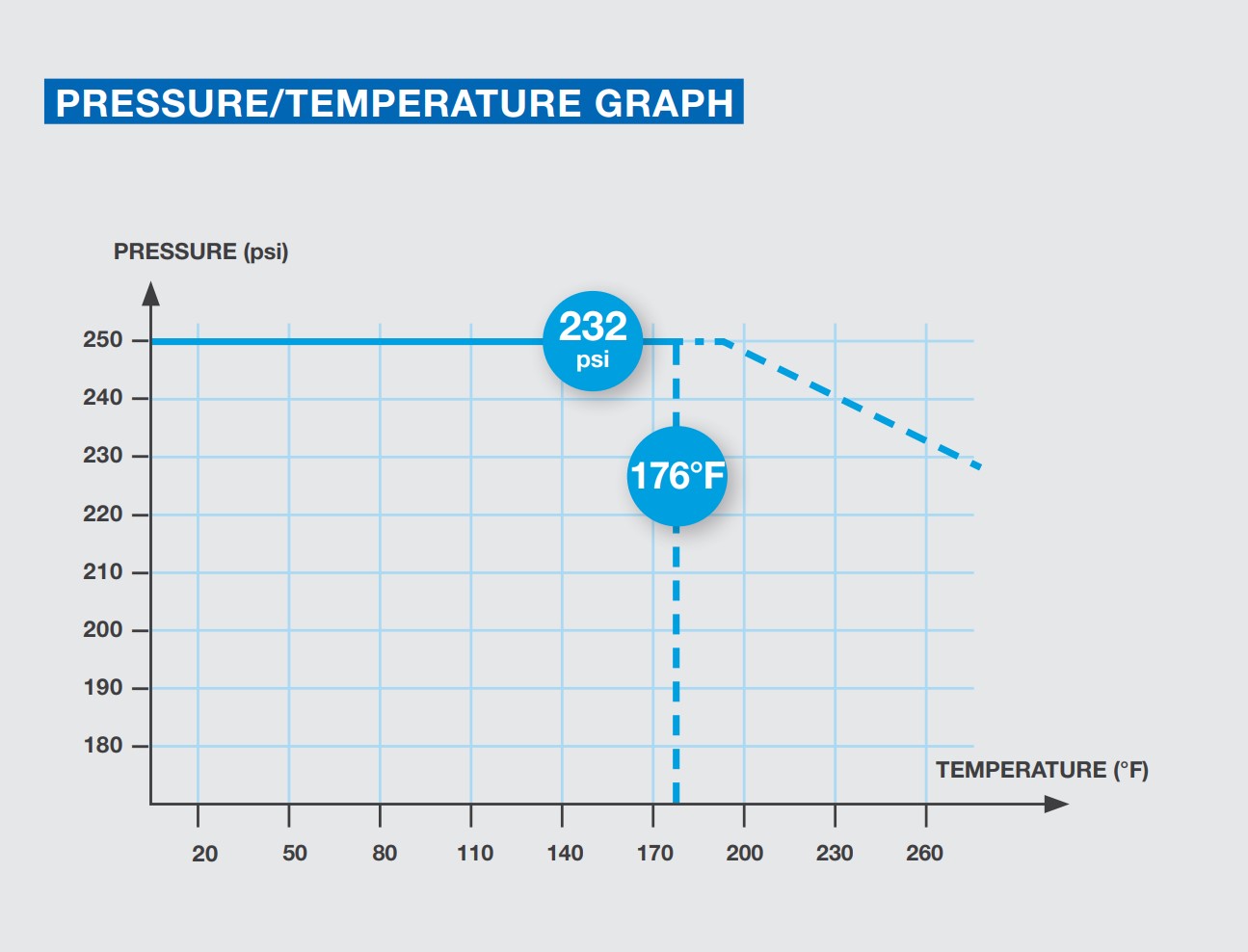

- an operating pressure range from -14.21 psi to + 232 psi

- a temperature range from - 4°F to + 176°F

Workstations are well supplied, accessible and ergonomically designed. The facility is durable and can be easily upgraded.

Presentation of the PPS range in video

Benefits of a PREVOST PIPING SYSTEM

- Compact and lightweight

The 100% aluminum composition of the PPS range creates a system that is compact, lightweight and durable. - High tech, modern material

Aluminum alloy, combined with external electrostatic paint and internal treatments all protect the pipe against the oxidation and corrosion. - 100% customizable

The wide range of sizes and fittings allows the system for modular and scalable construction. - Easy and quick to assemble

Simply insert the pipe into the PPS fitting then tighten the nut. - Leak free with minimal pressure loss

The "PPS Grip Concept" creates a secure, leak free connection. The smooth internal surface generates a laminar flow, a low friction coefficient and a maximum flow diameter which are all factors to reduce pressure loss. - Compatible with compressor oils

Aluminum and viton seals are compatible with compressor lubricants. - Tough material

Aluminum guarantees long term performance: mechanical strength, pressure resistance and shocks absorbent

The PREVOST PIPING SYSTEM range

100% aluminum pipes

- Anti-corrosive material

- Minimal pressure loss

laminar flow from smooth internal surface - UV and heat resistant

low coefficient of expansion - ISO marking and colour

all diameters are available for RAL 5012 (blue) and RAL 7001 (gray) pipes. 3/4”, 1” and 2” diameters are also available for RAL 6029 (green). - No fire hazard

system does not require a fire permit - Simple tools

easy to cut and chamfer for simplified installation and maintenance - Lightweight

- Cost-effective

TECHNICAL CHARACTERISTICS OF PPS PIPE

Material:

Extruded aluminum.

Aluminum alloy EN AW 6060 T6 UNI-EN 573-3

Aluminum alloy EN AW-6063 T6

Treatment:

Internal/external treatment (RoHS compliant)

Coating:

Electrostatic paint

Extrusion quality:

Calibrated without welding

Compatible fluids:

Compressed air, vacuum, neutral gases

Pipe lengths:

9.84’ or 18’

Density:

170 lb/ft3

Pipe outside diameter:

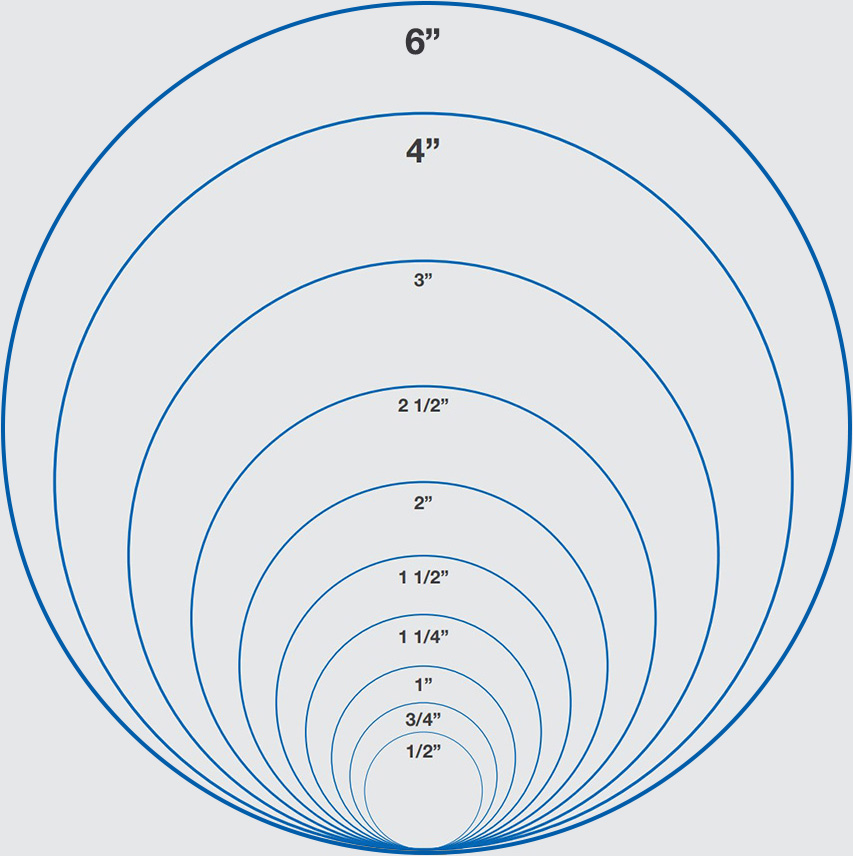

Ø 1/2, 3/4, 1, 1 1/4, 1 1/2, 2, 2 1/2, 3, 4, 6”

100% aluminum fittings

-

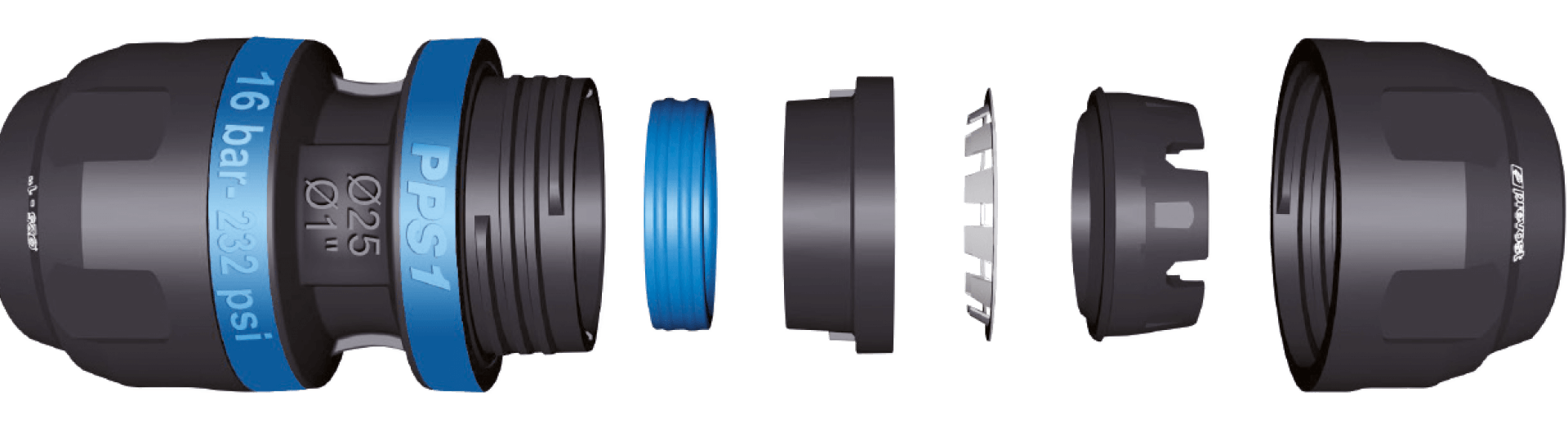

IDENTIFICATION

The Prevost logo is engraved on each fitting

-

DIAMETER

Pipe external diameter in mm and inches

-

PRESSURE

Maximum service pressure

(bar/psi) -

MARKER

To indicate that the pipe is correctly positioned in the fitting

-

LEAKTIGHT

The seal has been specifically designed for this application. It comprises two Teflon-coated lobes to optimize leaktight.

INTERNAL PARTS

Internal parts cannot be detached from the body after assembly.

-

TRACEABILITY

TECHNICAL SPECIFICATIONS OF FITTINGS

Body and nut:

100% aluminum EN AB 46100

PPS Grip Concept :

stainless ring

Tapping flange

to remove condensates

The PPS Grip Concept

The pipe is locked into the fitting with a stainless steel ring of teeth which penetrates the aluminum.

The double-lobed, lubricated seal guarantees a secure connection and provides optimum results even in the harshest working conditions.

CC CONCEPT: COMPACT CONNECTOR CONCEPT

Compact solution for directly connecting two fittings, optimizing space and creating installations suitable for "compressor" rooms.

- Compact

Save space in your installation by optimizising space. - Quick

The CC Concept allows two fittings to be connected directly. - Modular

Create specific installations adapted to all "compressor rooms".

Optimize your workstation with the PPS SQ compressed air network

The PPS SQ line transforms individual workstations into an air source. Design ergonomic, compact and aesthetic assembly bench to increase efficiency and productivity.

The PPS SQ line integrates seamlessly into a new or existing Prevost Piping System network by connecting directly into drops at:

- Automatic machine lines

- Individual workstations/workbench

- Pneumatic control cabinets

- Factory assembly

- Production lines

2024 range extension

The PPS range gets bigger!

Prevost has extended its range of compressed air pipework Prevost Piping System by adding 6" diameter to its size offering.

The PPS range, manufactured in Europe, offers the guarantee of a leak-free network, that is relatively simple to assemble using lightweight, impact-resistant aluminum pipe and fittings. It is now available for even the largest installations!

The compressed air system in practice

How to install your Prevost Piping System compressed air network?

How to attach your compressed air network?

Video content is available to help you install your compressed air network PREVOST PIPING SYSTEM.

Certifications by industry application

Industry standards

ISO 9001*

Prevost’s technology is recognized by the TÜV.

* Only valid for products manufactured in Italy

ASME QPS-1

Supplier quality guarantee

Worldwide exclusivity.

Pressurized equipment

PED-2014/68/EU

TÜV certifies Prevost products meet the requirements of the Pressure Equipment Directive PED 2014/68/EU.

ASME B31.1

Prevost PPS products comply with ASME B31.1.

ASME B31.3

Prevost PPS products comply with ASME B31.3.

CRN

Prevost PPS products meet Canadian pressure equipment requirements and are CRN certified.

Safety and protection

UL 723 - ASTM E84

The PPS compressed air system line complies with American standard UL 723 & ASTM E84 for fire behavior.

EN 13501-1

The PPS compressed air system line complies with European standard EN 13501-1 for fire behavior.

ATEX-2014/34/UE

This European directive applies to all electrical and non-electrical equipment used in explosive, gaseous or dusty atmospheres.

UV RESISTANT

The 100% aluminum PPS line has excellent ultra violet ray resistance.

Fluid quality

Oil Free

Prevost products will not contaminate the conveyed fluid with grease or oil particles.

Silicon free

Prevost guarantees that no silicone-based agents have been used in the manufacturing of PPS products.

NSF H1

The Prevost PPS AL lubricant meets the requirements of the most stringent applications: food, chemical, pharmaceutical, cosmetic...

ISO 8573-1 cl. 0.0.0

The products in the PPS range ensures the fluid being transported is not contaminated by solid particles, water, moisture or oil.

QUALICOAT

The outer surface of PPS aluminum pipes complies with Qualicoat certification.

Environmental

REACH

Prevost closely monitors the raw materials used to produce its line of PPS products.

RoHS

Prevost closely monitors the raw materials used to produce its line of PPS products.

Recyclable

The PPS line (pipes and fittings) are 100% aluminum and recyclable.

Support and documents

You will find below all our documentation related to the PREVOST PIPING SYSTEM air network range.

Materials lists and full quotations

Prevost's technical team creates custom network designs for your compressed air installation.

Preparation of diagrams and quotations on request according to your planned facility: general diagram, detailed drawing and a complete quote listing each item, the corresponding quantities, and the price of the proposed ringmain is provided for your consideration.