Upgrade your compressed air filtration system

Filtration, regulation and lubrication of compressed air

Optimize actuators and pneumatic tools efficiency

Filtering with mechanical separation removes solid particles (dust, shavings,...) and liquids (water or oil) from compressed air systems. Filtered compressed air directly impacts performance and lifespan of pneumatic tools and actuators. It's the basis of quality production.

Prevost Filtration system is specifically designed to meet the demanding requirements of industrial settings. With enhanced safety measures, efficient maintenance features and ATEX certification.

Presentation of the filtration range in video

Prevost Filtration range

Improved safety

The new Prevost Filtration range prioritizes security to ensure the safe operation of your compressed air system thanks to:

■ Cut-off Valve

A cut-off valve allows for quick and easy isolation of the compressed air supply when needed. It provides an additional layer of safety during maintenance or emergencies.

■ Lockable Element

To prevent unauthorized access or tampering, Prevost Filtration systems are equipped with lockable elements. This feature ensures that the system remains secure and free from unwanted interference.

■ Progressive Pressurization

Progressive pressurization is an innovative feature that gradually increases the air pressure within the system. This controlled process helps prevent sudden pressure surges, minimizing the risk of damage to equipment and ensuring a smooth operation.

■ ATEX Certified

Prevost Filtration systems are ATEX certified, providing peace of mind for operations in potentially explosive environments. The certification covers both Zone 1 and Zone 2 areas where flammable gases, vapors, or dust may be present. Additionally, Prevost Filtration is certified for Zone 21 and Zone 22, which pertain to areas where potentially explosive dust atmospheres may occur.

Prevost Filtration range

Easier maintenance

Efficient maintenance is vital for the longevity and performance of your compressed air filtration system thanks to:

■ Clogging Indicator

A clogging indicator provides real-time feedback on the condition of the filter. It alerts the operator when the filter needs to be cleaned or replaced, allowing for proactive maintenance and preventing potential issues caused by a clogged filter.

■ Condensate Recovery

Condensate, a byproduct of compressed air, can accumulate in the system and compromise its efficiency. Prevost Filtration systems feature condensate recovery mechanisms that efficiently remove this moisture, ensuring the system operates at optimal levels.

■ Integrated Pressure Gauge

An integrated pressure gauge allows for convenient monitoring of the air pressure within the system. By keeping an eye on the pressure levels, operators can ensure that the system operates within the desired parameters and take corrective action if needed.

Custom-made air treatment

Prevost Filtration: a modular range

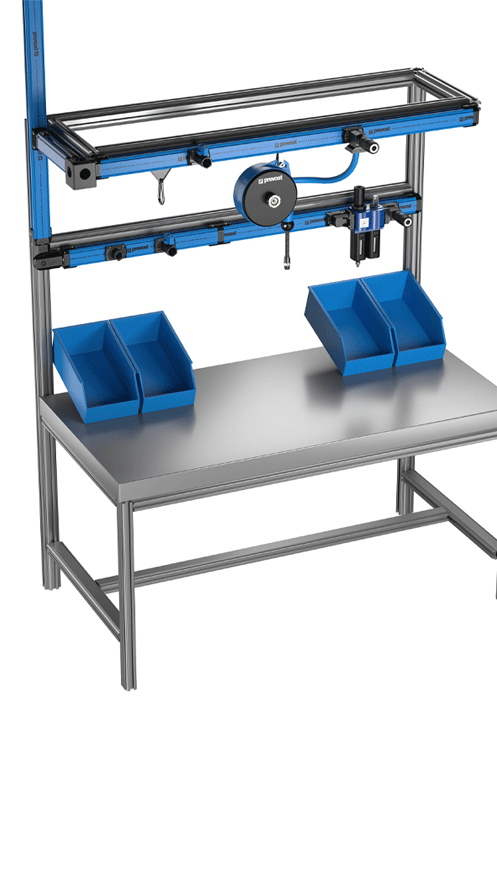

Prevost Filtration compact solutions create a complete and efficient compressed air chain to ensure the reliability of your pneumatic network. Mount units individually or grouped, offers a variety of possibilities. Select the options that work best for your specific applications.

Prevost Piping System compressed air network

Keep your piping system clean

Clean air throughout the network is essential for maintaining the reliability and longevity of the entire compressed air system. Prevost Filtration guarantees clean air flow, reducing the risk of downtime, improving overall production quality, and extending the service life of your equipment.

Transport compressed air right up to the point of use with one of our innovative, reliable solutions.

The PPS SQ range allows the transport of compressed air directly to the assembly workstations.

The Prevost Piping System 100% aluminium range comprises aluminium pipes and couplings that are compact, lightweight and robust. From Ø16mm to Ø100mm.